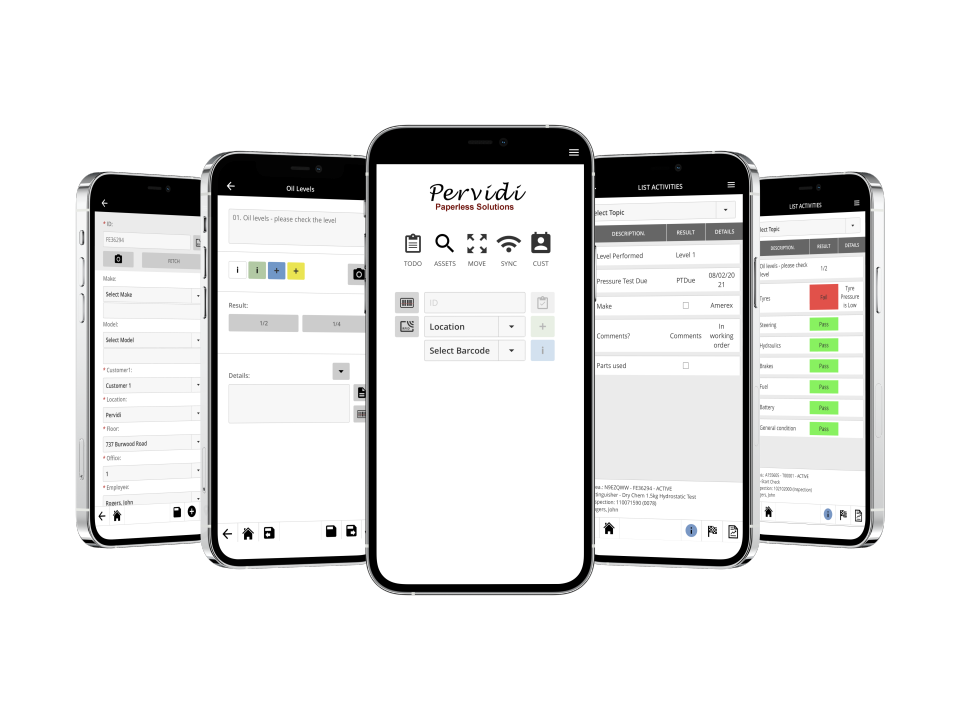

The integration of Artificial Intelligence (A.I.) into Pervidi represents a transformative leap forward for industries reliant on efficient inspections, such as mining, construction, utilities, manufacturing, and industry in general.

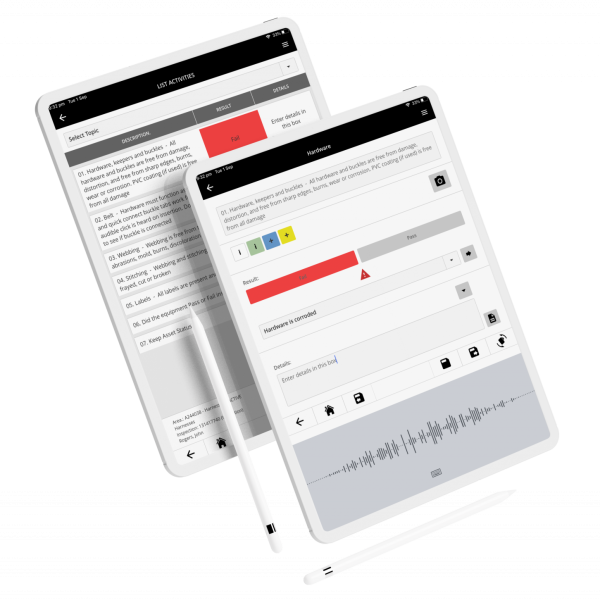

This technology not only enhances the accuracy and efficiency of inspections but also significantly reduces safety risks. We call our Game Changer