Presented in DRILLFEST 2023 (*)

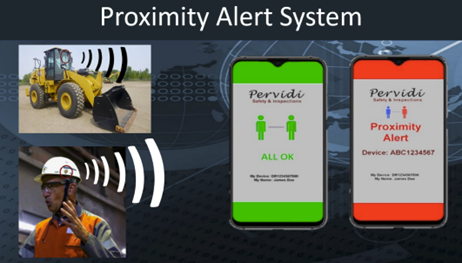

Safety is of paramount importance in the drilling industry, where workers face a myriad of hazards daily. In a presentation at Drillfest in Toowoomba October 2023, Naaman Shibi from Pervidi (paperless Solutions) discussed how proximity alert systems are poised to revolutionise safety measures in the drilling sector.

Proximity alert systems, said Naaman, also known as proximity warning systems or proximity detection systems, are invaluable tools for enhancing on-site safety.

“Their primary function is to continuously monitor the location of employees and provide an alert when they venture too close to mobile machinery, explosive areas, or designated no-go zones,” he said.

“While these systems find applications across various industries, their role in the drilling sector is particularly significant due to the inherent risks associated with drilling activities.”

Diverse types of proximity alert systems

Naaman highlighted the diverse range of proximity alert systems currently available, each with its unique set of advantages and limitations. These systems can be categorised as follows:

Camera-based proximity alert systems

These systems employ cameras to monitor and detect objects or individuals in real-time.

They provide visual information, offering a clear view of the surroundings.

“However, camera-based systems require a direct line of sight and can be hampered by adverse conditions such as mud, darkness, or dust,” Naaman said. “The cost may escalate when advanced features like AI for near-miss reporting are incorporated.”

Radar-based proximity alert systems

Radar technology is used in these systems for object detection. They do not depend on a direct line of sight, making them suitable for various environments.

“Radar systems may produce false readings due to interference or the presence of natural objects,” Naaman said. “While effective outdoors, they may have limitations when used indoors.”

Light-based proximity alert systems

Light-based systems utilise basic plug-and-play lights on vehicles or equipment with employees alerted through visual cues provided by the lights.

“These systems are passive and do not actively notify operators of employee presence,” Naaman said. “However, they are cost-effective and are commonly deployed in warehouse settings.”

Tags and Tablet-based proximity alert systems

Tags and Tablet-based systems rely on tablets and Bluetooth Low Energy (BLE) technology where each employee is equipped with a small BLE-enabled tab.

“This solution offers affordability and ease of installation without the need for extensive infrastructure and are Ideal for remote drilling sites that may lack internet connectivity,” Naaman said.

The Tags and tablet-based advantage

Naaman emphasised the advantages of tablet-based proximity alert systems, particularly in the drilling industry.

“Tags and Tablet-based solutions stand out as they do not necessitate additional infrastructure,” he said. “This makes them well-suited for remote drilling sites where setting up infrastructure might be challenging.”

“Tablets and BLE tags can also be rapidly deployed, ensuring quick implementation and the immediate enhancement of safety measures”.

“Tags and Tablet-based systems also operate independently of the Internet, guaranteeing reliability even in remote and isolated locations where internet access may be limited.”

A real-world case study

Naaman shared an insightful case study from the United States, where a drilling company faced operational challenges related to outdoor drilling activities. With the introduction of a tags and tablet-based proximity alert system, the company achieved notable improvements in safety. The system facilitated better collision avoidance among employees and vehicles, significantly enhancing safety on the job.

Future developments

In response to questions from the audience, Naaman mentioned that Pervidi was continually advancing its technology.

“While the current systems do not incorporate GPS, they remain open to further innovations based on industry needs,” he said. “This commitment to improvement promises continued advancements in safety measures within the drilling industry.”

In conclusion, Naaman said proximity alert systems were poised to revolutionise safety practices in the drilling industry.

“The choice of the right proximity alert system should be tailored to the specific needs and operational circumstances of the drilling site,” he emphasised. “With ongoing technological advances, safety measures in the drilling industry are on the brink of a revolution, ensuring that workers can carry out their tasks with greater confidence and security.”

“Tablet-based solutions stand out as they do not necessitate additional infrastructure or internet connectivity.”

(*) Published in ADIA magazine January 2024